CAPABILITIES

SYSTEMS

ENGINEERING

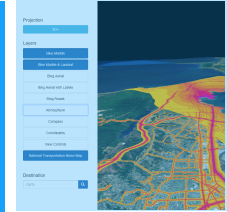

Optimization and Evolutionary Improvement of Simulation Facilities and Air Traffic Management Research Systems

Our systems engineers have the knowledge and experience required to design and develop new simulators and/or simulation capabilities, and seamlessly integrate and verify system upgrades. They are able to perform systems analyses, design simulator systems/subsystems, and develop implementation plans for software/hardware development as well as conduct verification/validation testing of new components or interfaces. Our engineers integrate advanced technology capabilities into simulation systems, including the development of advanced engineering techniques to improve simulation fidelity and validity. Their expertise is both broad and deep, with the ability to design, implement and test networks, software and hardware infrastructure, software system architecture, and system interoperability. The goal of many upgrades is to reduce the overall cost of simulation development, maintenance, and operations, and our engineers continually demonstrate their ability to do so for our customers. Our systems engineers impact the broader aviation ecosystem through designing air traffic management systems for novel concepts and the next generation of commercial air transport, looking towards urban air mobility, air taxis, and integrated fleet management solutions.

SOFTWARE

ENGINEERING

Expertise in developing systems, applications, infrastructure software for modeling, simulation, and research

Our software engineers have a wide variety of opportunities to challenge and grow their skillsets. Projects include developing, integrating, and verifying specialized software such as real-time schedulers, debug packages, simulation development tools, input/ output routines, special device drivers, and connecting distributed systems and simulations between facilities and across the country. Our software engineers are leading the way at NASA as they leverage the power of cloud services for advancing software development and verification, use super computers to analyze terabytes of data, and explore the potential for integrating artificial intelligence and virtual/augmented reality into simulation supporting aerospace research. We have pioneered automated development toolchains that allow us to deliver software faster and more reliably than before and are committed to advancing the software development ecosystem for our customers. These techniques allow us to rapidly prototype concepts and iterate alongside customers as design requirements change, keeping us on the forefront of any fast-paced project.

HARDWARE

ENGINEERING

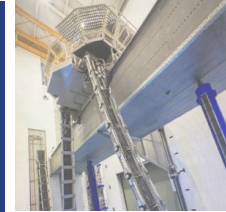

Providing a full spectrum of hardware engineering from design to operations

Our hardware engineers design, fabricate, modify, assemble, and integrate hardware and equipment for simulation research operations and discrete projects. They have the ability to fabricate original equipment from CAD design drawings as well as make modifications to existing mechanical hardware and systems. This includes, but is not limited to, cockpit display and instrument panels, floor panels and seats, visual display support structures, sheet metal assemblies, and inceptors (control devices such as center or side sticks, throttles, cyclics, and collectives). In addition, our hardware engineers design, develop, maintain, operate, and modify simulator mechanical, hydraulic, electrical/electronic, and servo systems.

MAINTENANCE & OPERATIONS

Optimization and Evolutionary Improvement of Simulation Facilities and Air Traffic Management Research Systems

Our maintenance and operations team members have years of experience operating and monitoring the performance of simulators, including the largest amplitude motion simulator in the world. They are adept in maintaining all simulation laboratory hardware including simulation engineer consoles/workstations, and audio/video/sensor equipment for data collection purposes. The M&O teams perform structural modifications to systems and facilities to meet research requirements, including supporting hardware-in-the-loop testing by integrating customer-provided hardware into simulators. Our far-reaching M&O capabilities are critical to ensuring the long-term viability and reliability of simulation systems, including modifying electronic chassis, assemblies/subassemblies and cables using a variety of techniques such as wire wrap, termi-point, and soldering; developing & maintaining simulator equipment operations and maintenance logs for usage/configuration and availability; performing discrepancy reporting via automated tracking systems; maintaining visual and graphics generation systems such as computer-generated out-the-window imagery systems, special symbology generators, and graphics workstations; maintaining control loaders and hydraulic power units; maintaining communications and audio systems (aircraft sound systems, voice input/output, radios, and intercoms); and maintaining cockpit instrumentation and displays.

SYSTEMS

ENGINEERING

Optimization and Evolutionary Improvement of Simulation Facilities and Air Traffic Management Research Systems

Our systems engineers have the knowledge and experience required to design and develop new simulators and/or simulation capabilities and seamlessly integrate and verify system upgrades. They are able to performing systems analyses, design simulator systems/subsystems, and develop implementation plans for software/hardware development as well as conduct verification/validation testing of new components or interfaces. Our engineers integrate advanced technology capabilities into simulation systems, including the development of advanced engineering techniques to improve simulation fidelity and validity. Their expertise is both broad and deep, with the ability to design, implement and test networks, software and hardware infrastructure, software system architecture, and system interoperability. The goal of many upgrades is to reduce the overall cost of simulation development, maintenance, and operations, and our engineers continually demonstrate their ability to do so for our customers. Our systems engineers impact the broader aviation ecosystem through designing air traffic management systems for novel concepts and the next generation of commercial air transport, looking towards urban air mobility, air taxis, and integrated fleet management solutions.

SOFTWARE

ENGINEERING

Expertise in developing systems, applications, infrastructure software for modeling, simulation, and research

Our software engineers have a wide variety of opportunities to challenge and grow their skillsets. Projects include developing, integrating, and verifying specialized software such as real-time schedulers, debug packages, simulation development tools, input/ output routines, special device drivers, and connecting distributed systems and simulations between facilities and across the country. Our software engineers are leading the way at NASA as they leverage the power of cloud services for advancing software development and verification, use super computers to analyze terabytes of data, and explore the potential for integrating artificial intelligence and virtual/augmented reality into simulation supporting aerospace research. We have pioneered automated development toolchains that allow us to deliver software faster and more reliably than before and are committed to advancing the software development ecosystem for our customers. These techniques allow us to rapidly prototype concepts and iterate alongside customers as design requirements change, keeping us on the forefront of any fast-paced project.

HARDWARE

ENGINEERING

Providing a full spectrum of hardware engineering from design to operations

Our hardware engineers design, fabricate, modify, assemble, and integrate hardware and equipment for simulation research operations and discrete projects. They have the ability to fabricate original equipment from CAD design drawings as well as make modifications to existing mechanical hardware and systems. This includes, but is not limited to, cockpit display and instrument panels, floor panels and seats, visual display support structures, sheet metal assemblies, and inceptors (control devices such as center or side sticks, throttles, cyclics, and collectives). In addition, our hardware engineers design, develop, maintain, operate, and modify simulator mechanical, hydraulic, electrical/electronic, and servo systems.

MAINTENANCE & OPERATIONS

Optimization and Evolutionary Improvement of Simulation Facilities and Air Traffic Management Research Systems

Our maintenance and operations team members have years of experience operating and monitoring the performance of simulators, including the largest amplitude motion simulator in the world. They are adept in maintaining all simulation laboratory hardware including simulation engineer consoles/workstations, and audio/video/sensor equipment for data collection purposes. The M&O teams perform structural modifications to systems and facilities to meet research requirements, including supporting hardware-in-the-loop testing by integrating customer-provided hardware into simulators. Our far-reaching M&O capabilities are critical to ensuring the long-term viability and reliability of simulation systems, including modifying electronic chassis, assemblies/subassemblies and cables using a variety of techniques such as wire wrap, termi-point, and soldering; developing & maintaining simulator equipment operations and maintenance logs for usage/configuration and availability; performing discrepancy reporting via automated tracking systems; maintaining visual and graphics generation systems such as computer-generated out-the-window imagery systems, special symbology generators, and graphics workstations; maintaining control loaders and hydraulic power units; maintaining communications and audio systems (aircraft sound systems, voice input/output, radios, and intercoms); and maintaining cockpit instrumentation and displays.